About

The CS3B, Centre

for Simulation in Bioengineering, Biomechanics, and Biomaterials,

has been working for over 20 years in research in the field of

bioengineering, biomechanics, and biomaterials using numerical

methods, especially the finite element method. The main research

focus of the group throughout these years has been to develop finite

element models of biomechanical structures, to perform validation

between experimental results and the answers obtained through

modeling and computer simulation, and to develop new products in the

field of bioengineering. It has assisted in the research of several

partners in bioengineering/biomechanical innovation.

The Centre has supported research with several partners

in the area of innovation in bioengineering/biomechanics. We have

experience in various topics: dental prostheses, bone fixation

plates, biomaterials, bioabsorbable stents, and medical equipment.

Active projects can be viewed at:

https://cs3b.feb.unesp.br/en/#work. Our laboratory is located at the

Engineering College of Bauru (FEB), São Paulo State University

"Júlio de Mesquita Filho", São Paulo State, Brazil.

Vision, Mission and Values

Vision

To become a reference in numerical simulation applied to biomechanical structures and bioengineering.

Mission

To promote research and development of bioengineering and biomechanics fields in Brazil and abroad through collaboration with other research centres, private companies and funding agencies.

Values

- Respect for the human being; - Engagement - Proactive attitude - Innovative spirit - Teamwork - Ethics and impartiality.

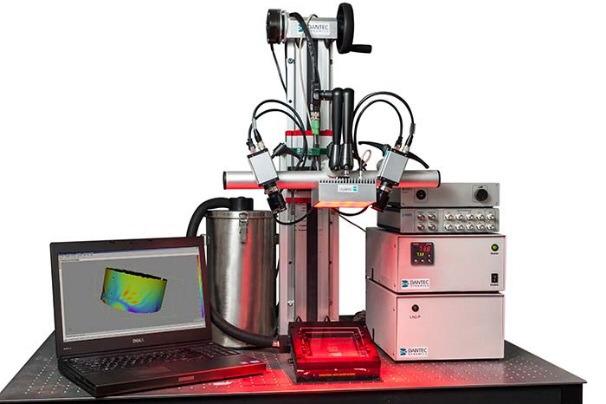

Infrastructure

The CS3B has equipment and software that help

in the development of projects.

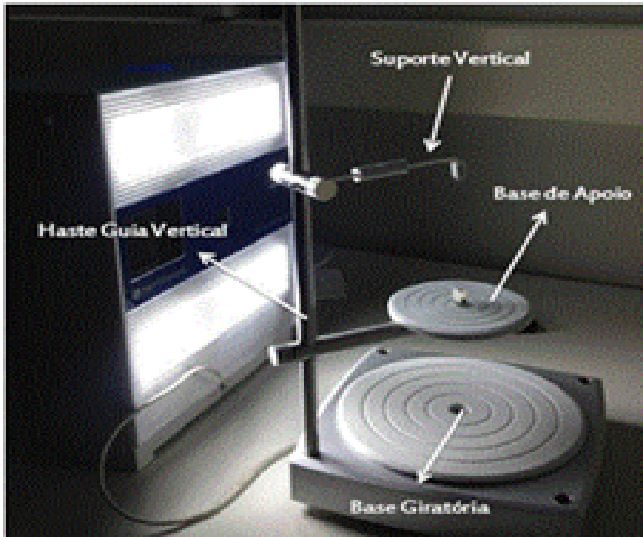

2) Next Engine 3D Scanner HD

3) Ansys Research Software v2022 (ANSYS Ansys Inc., Pennsylvania, USA)

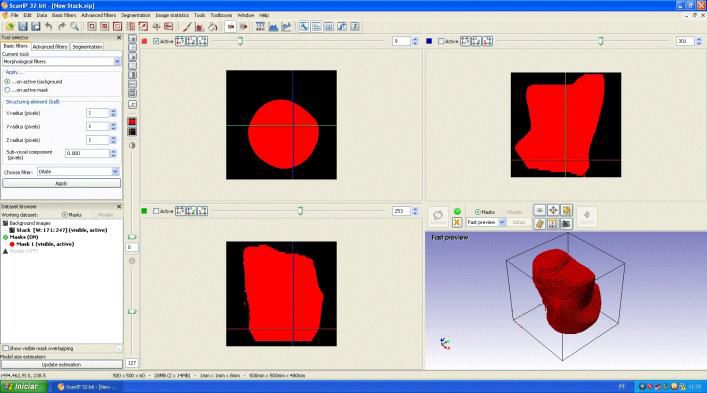

4) Simpleware Synopsis ScanIP (v2022, Simpleware Synopsys, California, USA)

5) Data acquisition device (NIDAQ-9172, National Instruments Corp.,Austin, Texas, USA)

People

We are a group of researchers and students with several and different backgrounds that got together to promote research and scientific advances in bioengineering and biomechanics using numerical methods.

Prof. Dr. Edson Antonio Capello Sousa

Coordinator - UNESP/Bauru

Specialist in finite element modelling of biomechanical structures

Dr. Bruno Agostinho Hernandez

Research Partner - UNESP/Guaratinguetá

Specialist in finite element modelling and analysis of biomechanical structures

Prof.Dr. Marcelo Sampaio Martins

Research Partner - UNESP/Guaratinguetá

Specialist in experimental analysis of stresses and deformations in elastic regime structures

Prof.Dr. Vinícius Carvalho Porto

Research Partner - USP/Bauru

Specialist in odontology, with focus on removable prosthesis, acrylic resin, acrylic oral prosthesis bases, desinfection and biofilm

Prof. Dr. Paulo José Paupitz Gonçalves

Research Partner - UNESP/Bauru

Specialist in rigid, plastic and elastic body dynamics

Prof. Dr. José Henrique Rubo

Research Partner- USP/Bauru

Specialist in odontology, partial-fixed dental prosthesis and CAD/CAM systems

Research Projects

The CS3B, Centre for Simulation in Bioengineering, Biomechanics and Biomaterials, has been conducting high quality pieces of research for over 20 years about a wide range of subjects related to the bioengineering, biomechanics and biomaterials fields.

The main group's research focus over these years were the development of finite element models of biomechanical structures, the validation of experimental results and the analysis of the responses obtained through computer modeling and simulations, and the development of new components in bioengineering.

The group has assisted several research partners in the area of innovation in bioengineering/biomechanics. We have experience in several research topics: dental prostheses, bone fixation plates, biomaterials, bioabsorbable stents and medical equipment. Active projects can be seen at: https://cs3b.feb.unesp.br/#work

Current Projects

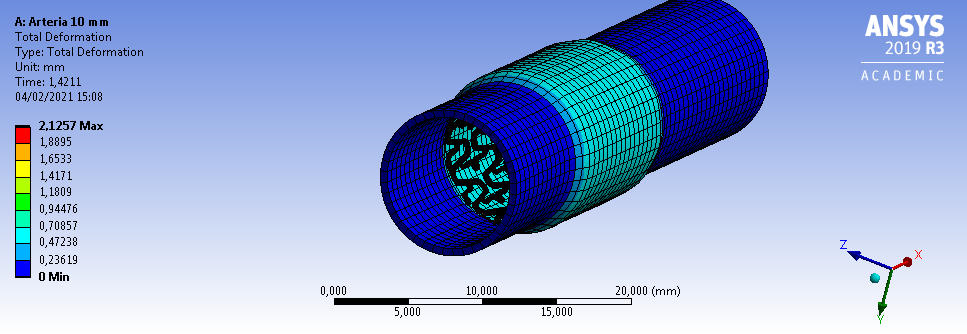

1) Project Name: Bioabsorbable Stent for Aortic Coarctation

Researchers: MSc. Flávio José dos Santos, Marcel Bergamo Machado, Dr. Bruno Agostinho Hernandez, Dr. Edson Antonio Capello Sousa e Dr. Aron José Pazin de Andrade.This project aims to develop a new bioabsorbable stent for the treatment of Aortic Coarctation in children. This stent will be numerically optimised using the finite element method to make the thickness of the stent rods as thin as possible while providing enough radial resistance and flexibility to support the aortic vessel pressure in Aortic Coarctation.

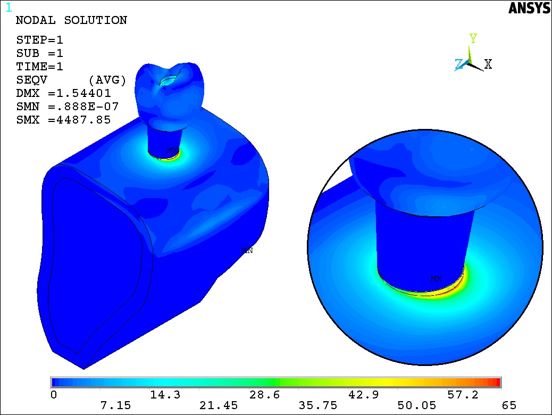

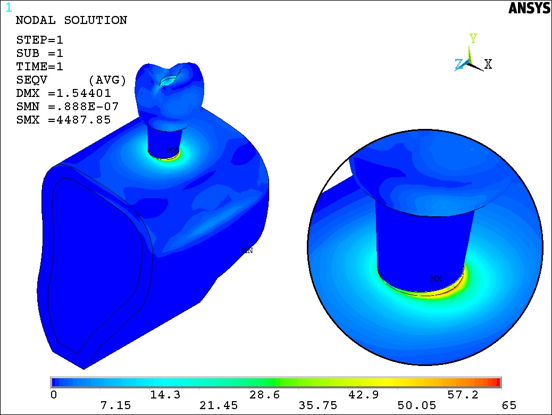

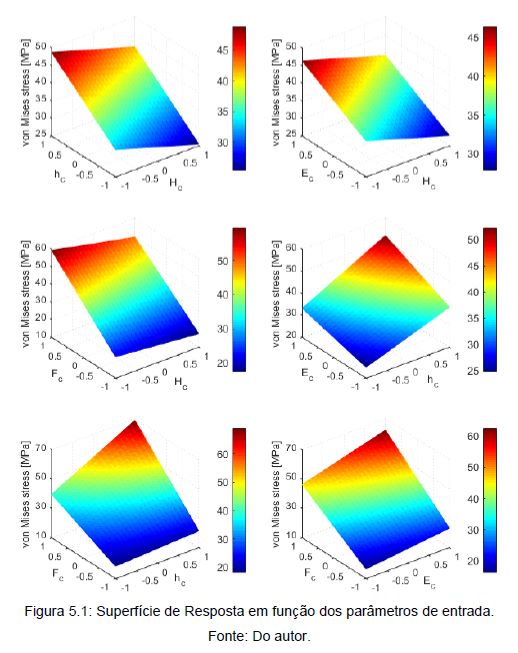

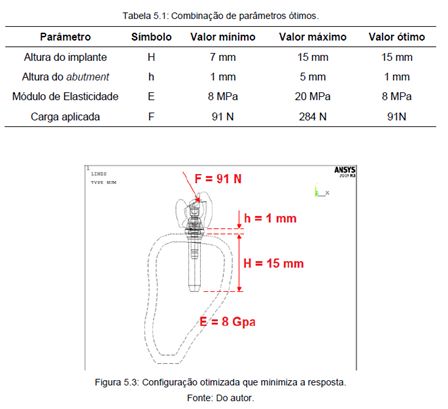

2) Project Name: Analysis and geometry optimisation of dental prosthesis using the finite element method.

The aim is to analyse the influence of structural parameters in the mechanical behaviour of dental prostheses using the Finite Element Method. At the same time, such structural parameters will be optimised using RSM (Response Surface Methodology) and DOE (Design of Experiments) techniques to minimise stress levels on the cortical bone region in the interface between bone and implant.

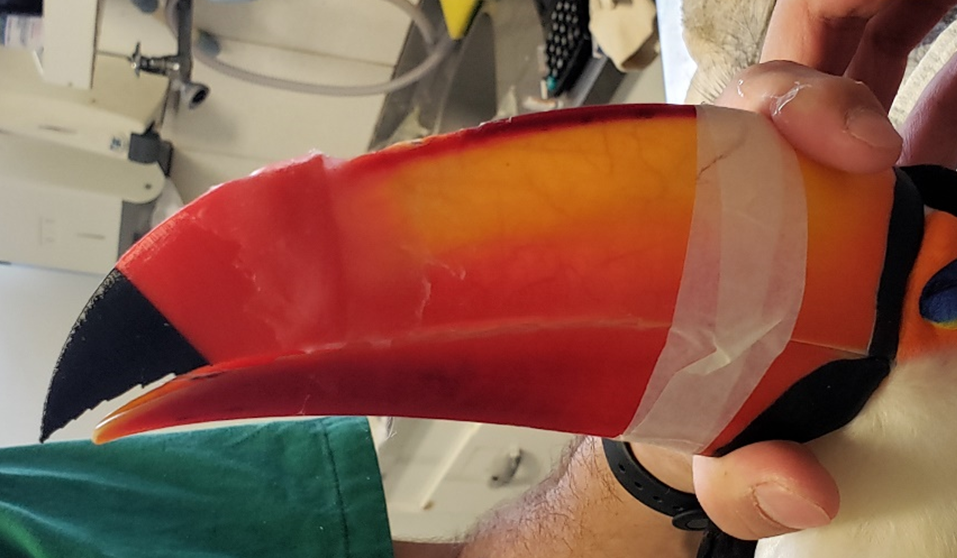

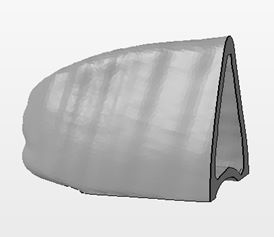

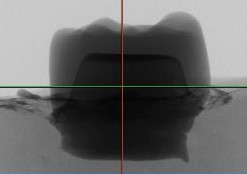

3) Project Name: Development of a beak prosthesis for toucan using 3D printing technologies

3D printing technologies are becoming increasingly accessible worldwide. At the same time, the veterinary prosthesis market is being driven by the growing number of treatments and prosthesis available for animals. However, most of the prosthesis available in the market are expensive and usually do not anatomically fit the animal fracture geometry. In this context, the present work aimed to develop a beak prosthesis for an injured toucan. A framework was established for the production of the prosthesis, including CAD and finite element modelling and structural analysis.

4) Project Name: Finite element and fatigue analysis of monolithic lithium disilicate dental crowns prepared using in CAD / CAM technology

This project aims to evaluate the fatigue strength and the stress distribution on monolithic lithium disilicate dental crowns using finite element models. Preparation design and the spacing between cement and the base will be evaluated.

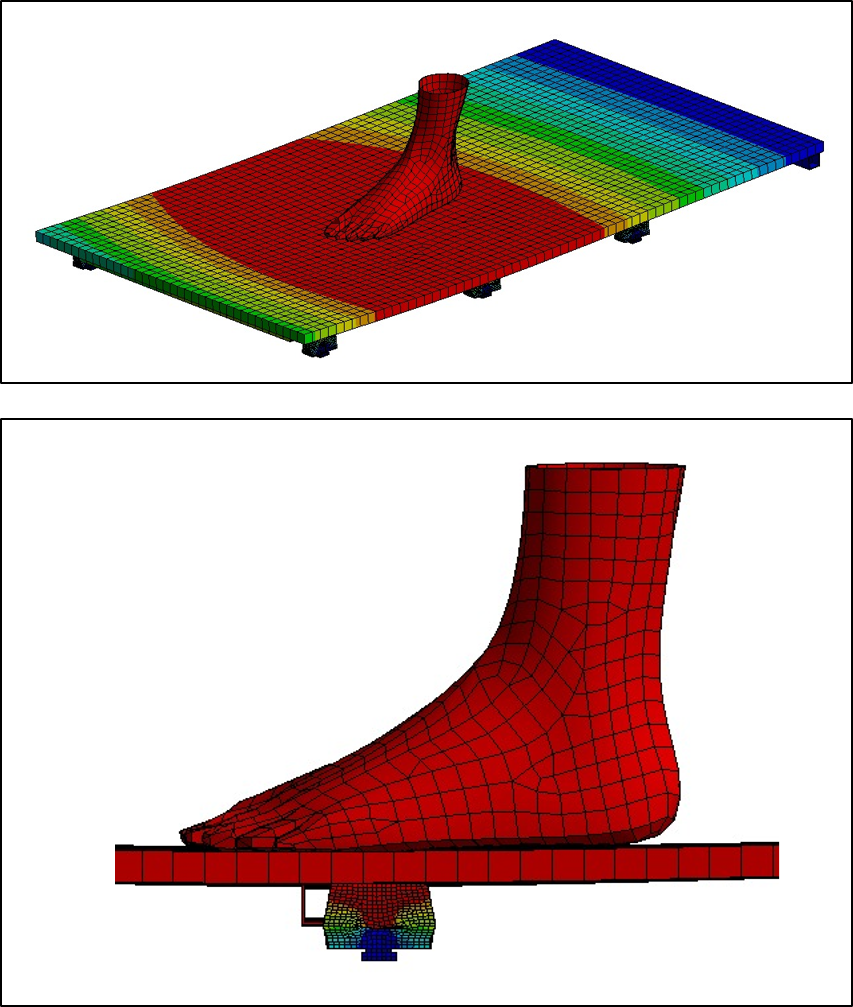

5) Project Name: Impact Absorption System on Treadmills: Numerical Simulation and Optimization Using the Finite Element Method

This project aims to increase the efficiency of the impact absorption system of treadmills by optimising the geometry and material, making it adaptable to a wide range of users and weights, thus, reducing the chance of injury caused by the practice of exercises.

6) Project Name: Development of a ceramic zirconia composite with the addition of nanoparticles

Researchers: Jean Franco Burgos Trilli, Dr. Vicente Gerlin, Dr. Bruno Agostinho Hernandez, Dr. Edson Antonio Capello Sousa, Dr. Cesar Renato Foschini.Ceramic materials are widely used as biomaterials, with application in different biological fields (medicine, odontology, pharmaceutics) and several projects and research are developed to find different application for ceramics as biomaterials. Zirconia (ZrO2) became an extensively used ceramic mainly for dental implants and prosthesis, as zirconia has high hardness, great wear resistance, biocompatibility and, mainly, high fracture toughness when compared to other ceramics, being even called ‘ceramic steel’. Even with these great characteristics, researchers look for changes in zirconia properties, to enhance even more its fracture toughness, adding different components to its ceramic matrix. This Project aims to enhance zirconia fracture toughness creating a ceramic based composite material adding carbon nanotubes on its matrix. The addition of nanocomponents to a zirconia matrix has shown promising results in different researches and the nanotubes behaviour acting as crack control mechanisms, retarding and blocking crack propagation is important to enhance zirconia toughness. Using conventional sintering methods and understanding the composite fabrication process, the main objective is to study carbon nanotubes influence on a zirconia matrix and how they affect its mechanical properties, checking the composite quality and performance when compared to pure commercial zirconia. Evaluating mechanical properties with tests and advanced microscopy techniques, this Project aims to study and understand the difficulties in producing a ceramic-based composite and optimise the process of carbon nanotubes addition to ceramic matrices.

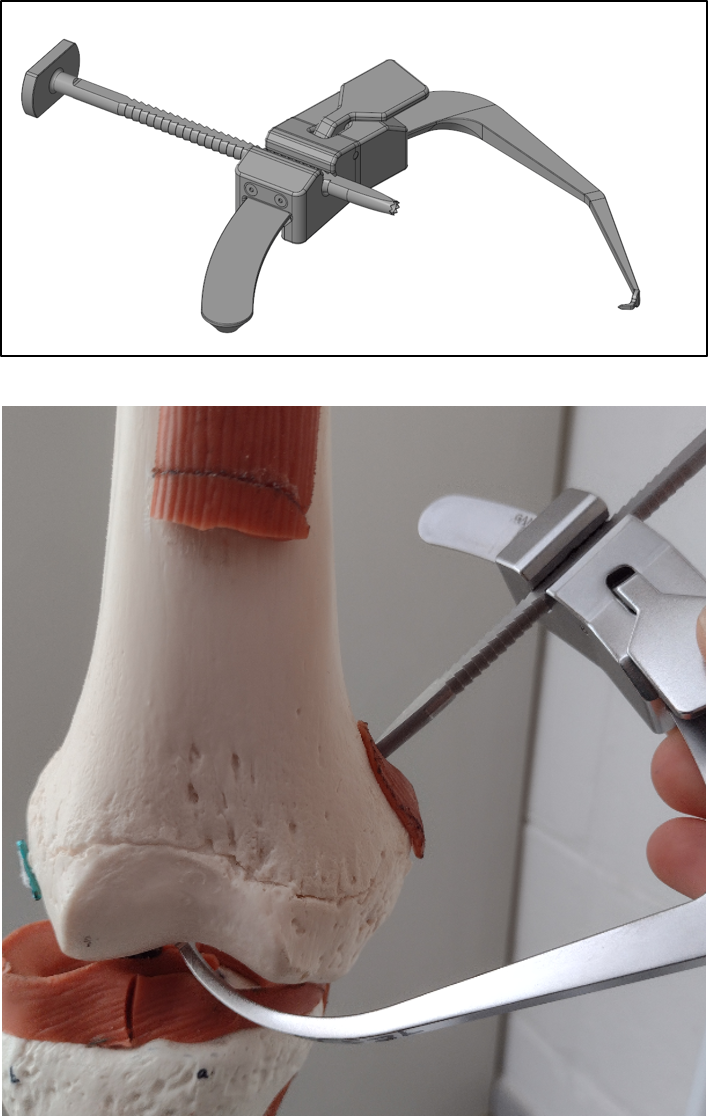

7) Project Name: Development of an orthopaedic surgical instrument in polymeric material

This project aims to develop a disposable surgical instrument for knee ligament repair made of polymeric material. During this study, the initial geometry of this new instrument will be optimised by means of finite element analyses aiming to obtain the maximum mechanical strength. It is expected to obtain an instrument that supports the loading conditions during surgery.

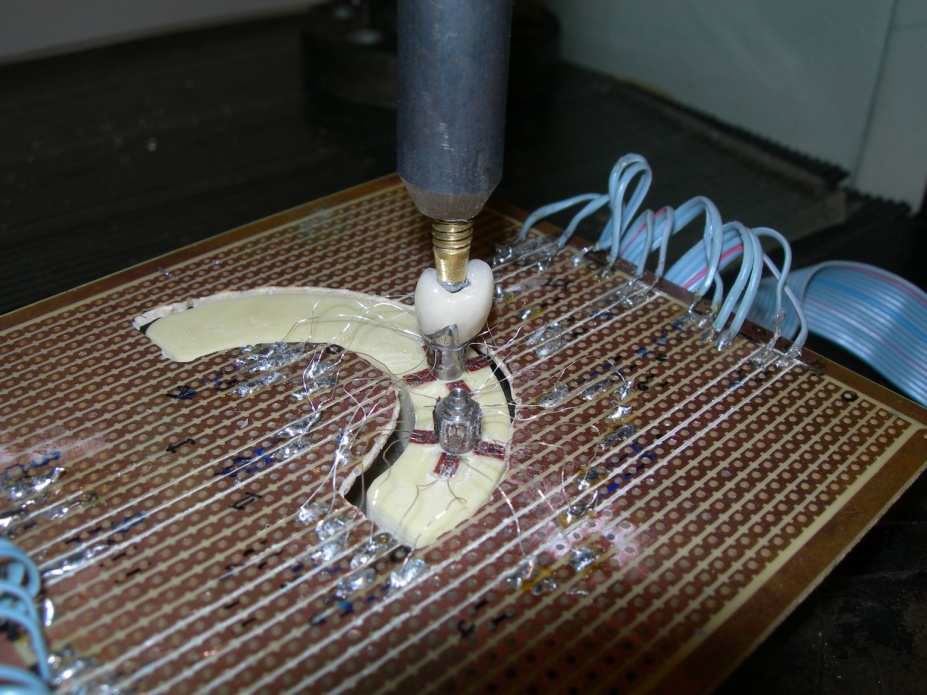

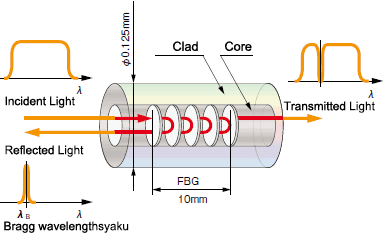

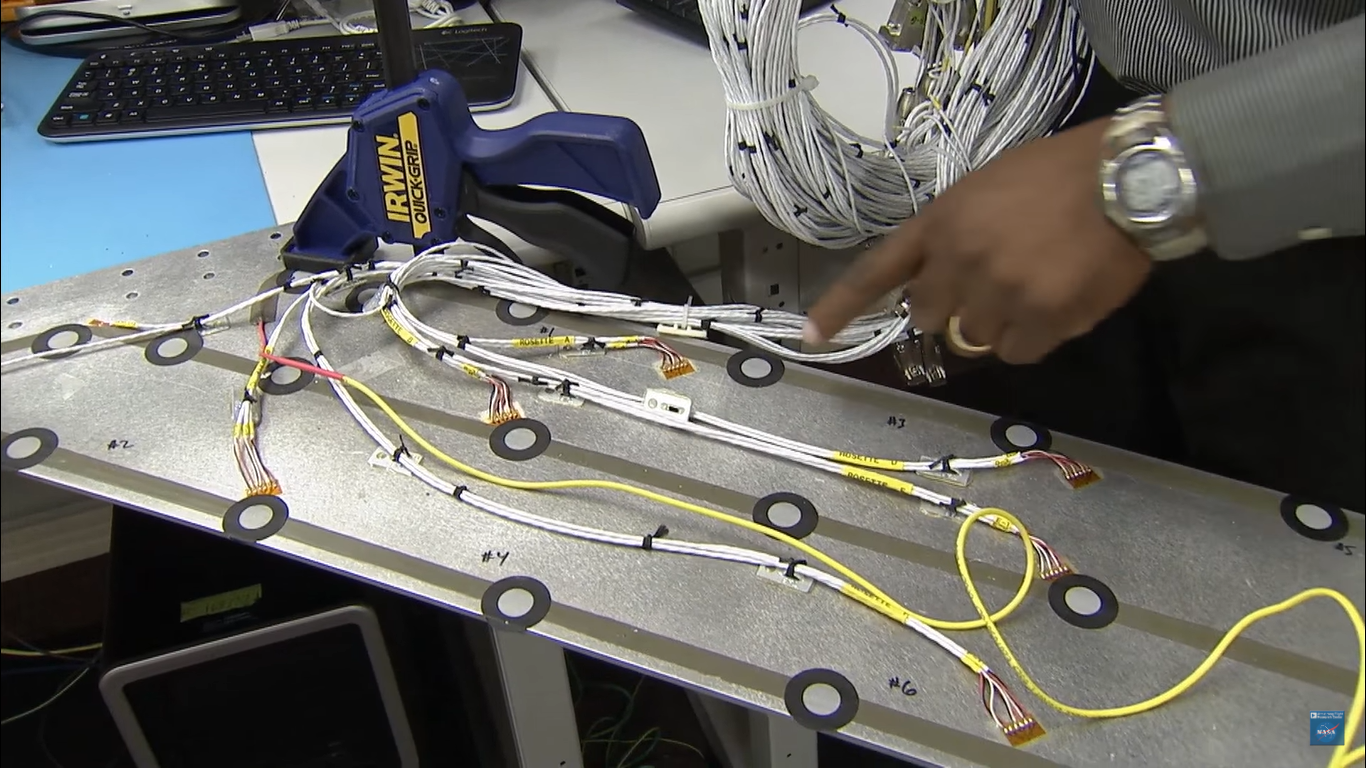

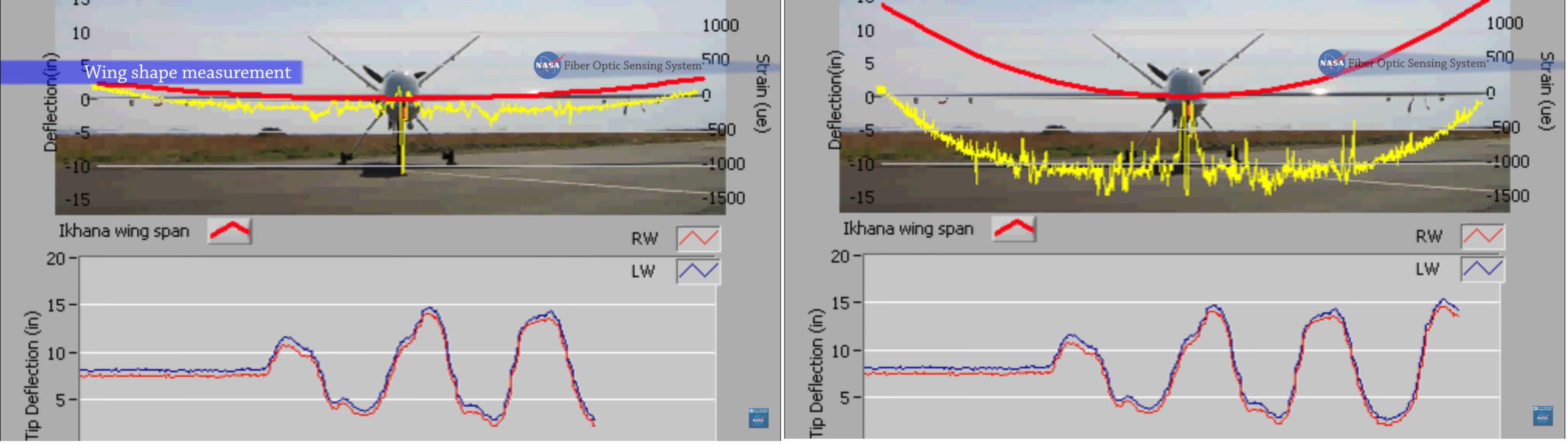

8) Project Name: Use of fiber optic sensors FBG (Fiber Bragg Grating), intended for measuring deformations – Review Work and Case Study

Within the various types of optical sensors, one type is Fiber Bragg Grating (FBG). Since its discovery, FBG has gained great attention in the field of optical sensing due to its inherent advantages such as low cost, small size, responsiveness, high accuracy, high sensitivity and immunity to electromagnetic interference. One of the applications of the optical sensor with FBG is the monitoring of the integrity of the structure, aiming to enable the prediction of structural failures and the execution of preventive maintenance at the right time, in addition to also helping in the measurements of structural deformations. The aim of this project is to carry out a literature review of the FBG and to analyze its viability in the analysis of structural stresses and deformations.

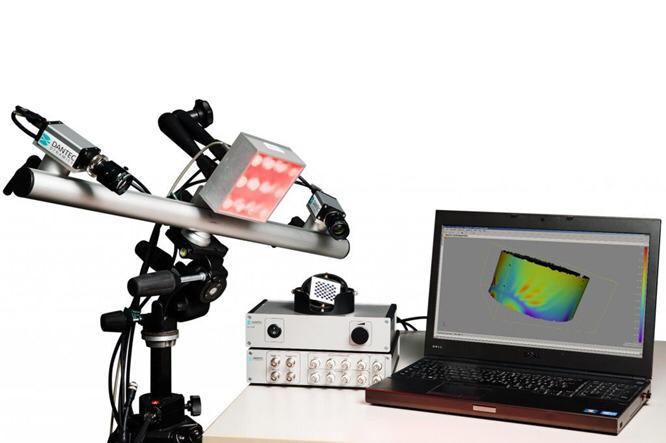

9) Project Name: Use of Digital Image Correlation (DIC) technology, for measuring deformations - Review work and case study.

The aim of this work is a literature review about the application of DIC - Digital Image Correlation. The DIC is a non-invasive way of carrying out stress and strain measurements tests. It has several advantages when compared to the usual methods (Strain Gauges), such as: there is no need for contact, strain measurements from 0.01 to 100%, possibility measurement in 2D and 3D, the size of the analyzed object can vary from microscopic scale to large structure, among others. The analysis process is carried out through a digital image correlation technique of the surface of the structure while it is subjected to loading. In this analyzed section, there are randomly spaced points (speckle pattern) before, during and after loading (the subsets), so the program can correlate the fields of in-plane (two-dimensional) or out-of-plane (three-dimensional) displacements of them that vary due to stress and/or deformation of the structure. The images are obtained through CCD cameras that allows the visualization of the surface of the object under analysis.

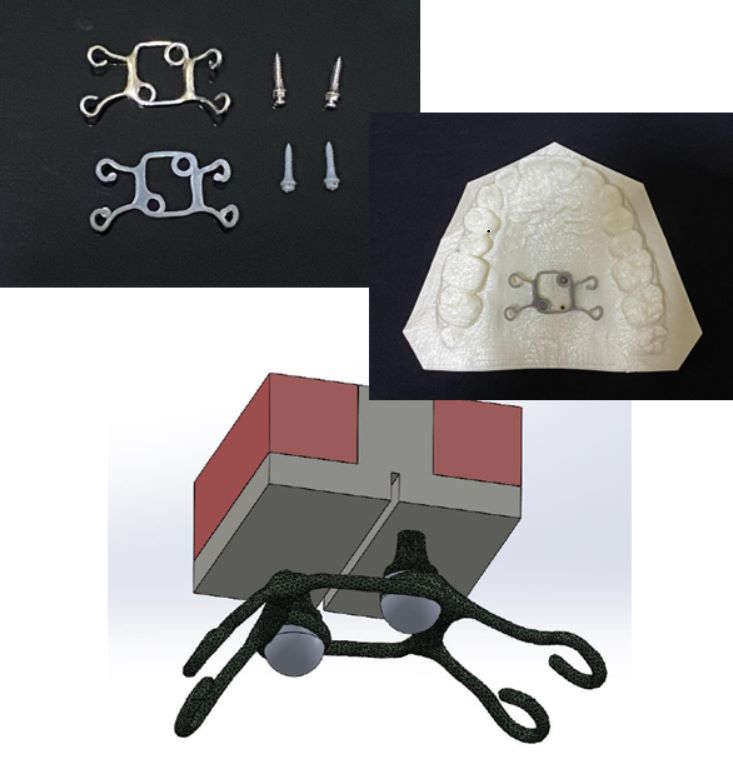

10) Project Name: Finite element analysis of palatal appliances, mini-implants and peri-implant bone generated by upper molar intrusion system

Anterior open bite is a common bone malformation in humans. It is characterized by the pointing of the upper teeth towards the outside of the mouth. Its correction can be done in two ways: through surgical procedures or through the use of specialized orthodontic appliances. Surgeries are very invasive procedures and their recovery is painful for the patient. Because of this, preference is given to orthodontic devices in the treatment. However, most of these devices are made by a few companies on the market, which makes their use very expensive. Therefore, there is a need to develop a low cost and effective device in the treatment. From this, studies on the fabrication and structural resistance of devices elaborated within the clinics gained importance and the Finite Element Method became a widely used tool in these studies. This project aims to evaluate the structural behavior of two new models of open bite correction devices developed in the clinic. For this, stainless steel wires and simple modeling of the mouth of a 32-year-old patient will be used so that it is possible to evaluate the behavior of stresses by the von-Mises criterion.

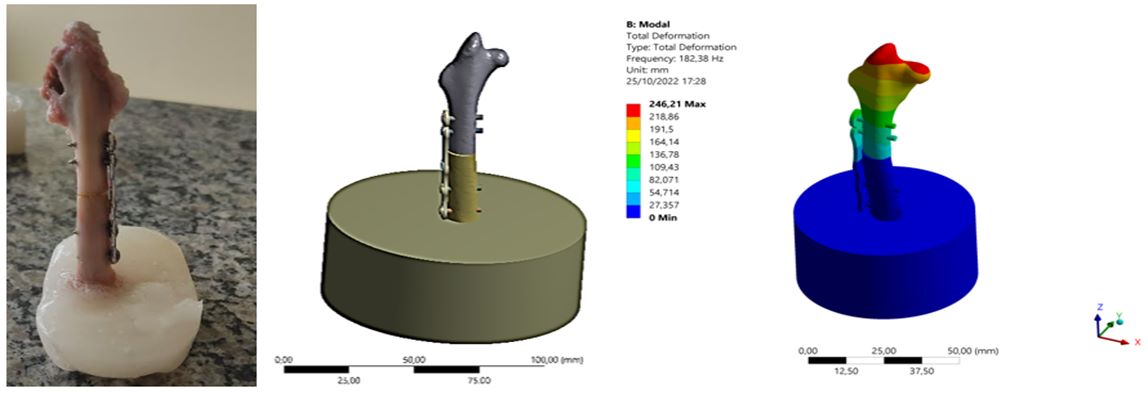

11) Project Name: Evaluation of different drilling techniques in the process of assembling a bone plate applied in the treatment of femoral fractures in rabbits via the Finite Element Method

The project aims to evaluate the structural behavior of different drilling techniques, with and without overdrilling, in the assembly of bone plates applied in the treatment of femoral fractures in rabbits, using a Finite Element model built from CT scans obtained from specimens tested in the laboratory, whose results will be later compared and used for model validation.

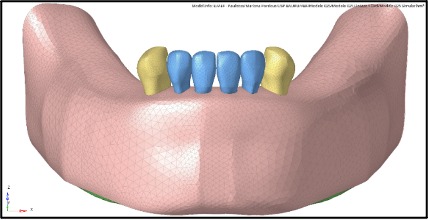

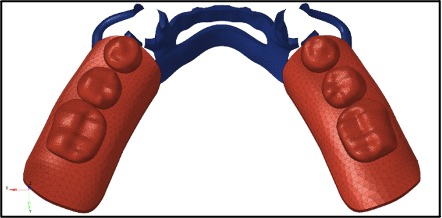

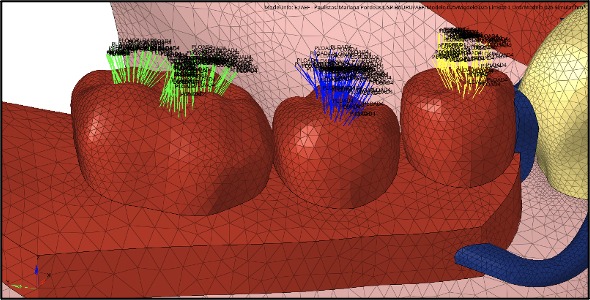

12) Project

Name: Determination

of the effect of orthodontic removable partial dentures

through finite element analysis

The main reason for the applications of removable partial dentures (RPDs) in dentistry is the replacement of lost teeth, either for aesthetic purposes, to increase the efficiency of chewing or improve phonetics. The fact that dental implants or partial dentures landlines are relatively inaccessible financially for much of the population. population, makes PPRs the best option for these patients. The PPR is consisting of a metallic frame, which must be planned and designed from a previous study of the models in an eyeliner and drawn correctly, aiming find the ideal position of each element in the PPR, in order to obtain a satisfactory biomechanics of the prosthesis in question, with adequate resulting forces in the teeth, mucosa and adjacent tissues. To obtain adequate mechanical retention in a PPR, direct retainers must be planned, in the abutment teeth, and the indirect, as far as possible from the fulcrum line. Indirect retainers are fundamental devices in the stability of the PPR, since they prevent the posteroanterior movement of the prosthesis, in addition to improving the distribution of forces between the remaining teeth, thus not overloading the abutment teeth. Currently, there is still little scientific evidence about which indirect retainer provides the better relation of distribution of forces between the teeth and therefore the modeling and finite element analysis (FEM) becomes an important tool in research dentistry, enabling the simulation of both cross-sectional clinical experiments how longitudinal. FEM is one of the numerical methods of solving equations differentials whose basic principle is to divide or discretize the system into several smaller elements called finite elements, identify the degrees of freedom that describe its behavior and then write the equations that describe the behavior of each element and its interaction with neighboring elements, what becomes very useful to indicate biomechanical aspects of materials that can hardly be tested in vivo. The objective of this work is to evaluate, through of the MEF, the influence of different models of PPRs in the distribution of efforts chewing aids on the remaining teeth and oral structures in patients who undergo use of PPR.

Publications

Our main publications. To know more, please visit researcher's profile.

- LONDON, EMILY ; HERNANDEZ, BRUNO AGOSTINHO ; MURRAY, JAMES ; GILL, HARINDERJIT S. . Using Suction in Back-Bleeding Conditions Increases Cement Penetration without the Need for a Tourniquet. MEDICAL ENGINEERING & PHYSICS, v. 1, p. 103807, 2022.

- DE OLIVEIRA FREITAS, JOÃO PAULO ; AGOSTINHO HERNANDEZ, BRUNO ; GONCALVES, P. J. P. ; BAPTISTA, E. ; CAPELLO SOUSA, EDSON ANTONIO. Novel and simplified optimisation pathway using Response Surface and Design of Experiments methodologies for dental implants based on the stress of the cortical bone. PROCEEDINGS OF THE INSTITUTION OF MECHANICAL ENGINEERS PART H-JOURNAL OF ENGINEERING IN MEDICINE, 2021.

- SANTOS, F. J. ; AGOSTINHO HERNANDEZ, BRUNO ; TOGASHI, M. M. ; ANDRADE, M. ; CAPELLO SOUSA, E. A. Desafios na modelagem de stents bioabsorvíveis em elementos finitos para coarctação da aorta. In: 9º CONGRESSO NACIONAL DE BIOMECÂNICA, 2020, Porto. LIVRO de RESUMOS do 9º CONGRESSO NACIONAL DE BIOMECÂNICA, 2020.

- M.M. TOGASHI, M.P. DE ANDRADE, F.J. DOS SANTOS, B.A. HERNANDEZ AND E.A. CAPELLO SOUSA. Preliminary Results of Structural Optimization of Dental Prosthesis Using Finite Element Method. In: XXVII Brazilian Congress on Biomedical Engineering. Proceedings of CBEB 2020, October 26-30, 2020, Vitória, Brazil.

- NEHEMY, GABRIELLA ; GONÇALVES, PAULO ; CAPELLO SOUSA, EDSON . Dynamic behavior of axially moving systems with elastic supports. In: 25th International Congress of Mechanical Engineering, 2019, Uberlândia. Proceedings of the 25th International Congress of Mechanical Engineering, 2019.

- PEREIRA, J. P. ; PEREIRA, J. M. ; GONÇALVES, G. M. B. ; CAPELLO SOUSA, EDSON A. O uso do escâner tridimensional a laser no ensino técnico profissionalizante em mecânica. In: XXVI Colóquio Afirse Portugal, 2019, Lisboa. XXVI Colóquio da AFIRSE Portugal, 2019. p. 241.

- PASCHOETO, G. G. ; MESQUITA NETO, CAMILO ; CAPELLO SOUSA, E. A. . Parametrization for Response Surface in a Dental Prosthesis with FEM Three-Dimensional Modeling. In: ENEBI 2018 - 6º Encontro Nacional de Engenharia Biomecânica, 2018, Águas de Lindóia. Anais do ENEBI 2018 ? 6º Encontro Nacional de Engenharia Biomecânica, 2018.

- MESQUITA NETO, CAMILO ; CAPELLO SOUSA, EDSON A. ; FERNANDES, J. C. M. ; MIDENA, R. Z. ; ALCADE, M. P. ; VIVIAN, R. R. . Development and Experimental validation of a Three-Dimensional Model in Finite Elements for Stress Analysis in an Endodontic Instrument. In: 24th ABCM International Congress of Mechanical Engineering - COBEM/2017, 2017, Curitiba. Anais do 24th COBEM/2017, 2017.

- KAVASHIMA, LIECA HASSEGAWA ; SANCHES, MATHEUS GALLO ; SOUSA, EDSON ANTONIO CAPELLO ; RAMOS, CARLA MÜLLER ; BORGES, ANA FLÁVIA SANCHES ; FORTULAN, CARLOS ALBERTO ; FOSCHINI, CESAR RENATO . Análise da microdureza Vickers de zircônia Y-TZP pré-sinterizada para a usinagem e posterior aplicação como copings. Materia-Rio de Janeiro, v. 22, p. e11817, 2017.

- JOAO, ROBERTO SARTORI MORENO ; CONRADO, DI RAIMO ; ROMEU, RONY DA COSTA CAVALCANTI ; MARCIO, AURELIO MONTEZUMA ; EDSON, ANTONIO CAPELLO DE SOUZA . Study of an electromechanical system for solid fertilizer variable rate planting. African Journal of Agricultural Research, v. 11, p. 159-165, 2016.

- SUEDAM, VALDEY ; MORETTI NETO, RAFAEL TOBIAS ; SOUSA, EDSON ANTONIO CAPELLO ; RUBO, José Henrique . Effect of cantilever length and alloy framework on the stress distribution in peri-implant area of cantilevered implant-supported fixed partial dentures. Journal of Applied Oral Science (Online), v. 24, p. 114-120, 2016.

- SANTOS, ROGERIO RODRIGUES ; RAHAL, SHEILA CANEVESE ; MESQUITA NETO, CAMILO ; RIBEIRO, CELSO ROBERTO ; SOUSA, EDSON ANTONIO CAPELLO ; FOSCHINI, CESAR RENATO ; AGOSTINHO, FELIPE STEFAN ; MESQUITA, LUCIANE DOS REIS . Biomechanical Analysis of Locking Reconstruction Plate Using Mono- or Bicortical Screws. Materials Research (São Carlos. On-line), v. 19, p. pp.588, n.3-593, 2016.

- REZENDE, CARLOS EDUARDO EDWARDS ; CHASE-DIAZ, MELODY ; COSTA, MAX DORIA ; ALBARRACIN, MAX LAURENT ; PASCHOETO, GABRIELA ; SOUSA, EDSON ANTONIO CAPELLO ; RUBO, JOSÉ HENRIQUE; BORGES, ANA FLÁVIA SANCHES . Stress Distribution in Single Dental Implant System. The Journal of Craniofacial Surgery (Print), v. 26, p. 2196-2200, 2015.

- HERNANDEZ, B. A. ; PASCHOETO, G. G. ; FREITAS, JOÃO PAULO DE OLIVEIRA ; PATERNO, A. ; CAPELLO SOUSA, E. A. Evaluation of Pre-load variation effects on the stress behavior in dental prosthesis: Finite Element Study. In: 23rd International Congress of Mechanical Engineering - COBEM 2015, 2015, Rio de Janeiro/RJ. Anais do COBEM-2015, 2015.

- AGOSTINHO HERNANDEZ, BRUNO ; PATERNO, ALEXANDER ; CAPELLO SOUSA, EDSON ANTONIO ; DE OLIVEIRA FREITAS, JOÃO PAULO ; FOSCHINI, CESAR RENATO . Fatigue Analysis of Dental Prostheses by Finite Element Method (FEM). In: ASME 2015 International Mechanical Engineering Congress and Exposition, 2015, Houston. Volume 3: Biomedical and Biotechnology Engineering. p. V003T03A081.

- FREITAS, JOÃO DE OLIVEIRA; CAPELLO SOUSA, E. A. ; FOSCHINI, C. R. ; SANTOS, R. R. ; RAHAL, S. C. Pretreatment and reconstruction of three-dimensional images applied in a locking reconstruction plate for structural analysis with FEA. In: Tavares, JMRS; Jorge, RMN. (Org.). (Org.). COMPUTATIONAL VISION AND MEDICAL IMAGE PROCESSING IV. 1eded.Funchal, Madeira Island: CRC Press, 2014, v. , p. 133-135.

- FREITAS, JOÃO DE OLIVEIRA; CAPELLO SOUSA, E. A. ; FOSCHINI, C. R. ; SANTOS, R. R. ; RAHAL, S. C. Pretreatment and reconstruction of three-dimensional images applied in a locking reconstruction plate for structural analysis with FEA. In: Tavares, JMRS; Jorge, RMN. (Org.). (Org.). COMPUTATIONAL VISION AND MEDICAL IMAGE PROCESSING IV. 1eded.Funchal, Madeira Island: CRC Press, 2014, v. , p. 133-135.

- DE OLIVEIRA, JOÃO ; BIANCO, VINÍCIUS ; RUBO, JOSÉ ; GONÇALVES, PAULO ; SOUSA, EDSON . Parametric evaluation of cortical bone thickness behavior on stress/strain of a dental implant. In: R . M . Natal Jorge; J . C . Reis Campos; Mário A . P . Vaz; Sónia M . Santos; João Manuel R . S . Tavares (Org). (Org.). Biodental Engineering III. 1eded.London: CRC Press, 2014, v. , p. 39-41.

- GRANDO, ANTÔNIO FRANCISCO ; REZENDE, CARLOS EDUARDO EDWARDS ; SOUSA, EDSON ANTÔNIO CAPELLO ; RUBO, JOSÉ HENRIQUE. Effect of veneering material on the deformation suffered by implant-supported fixed prosthesis framework. Journal of Applied Oral Science (Impresso), v. 22, p. 209-217, 2014.

- MENDES, STELLA DE N. C. ; EDWARDS REZENDE, CARLOS E. ; MORETTI NETO, RAFAEL T. ; CAPELLO SOUSA, EDSON A. ; HENRIQUE RUBO, JOSÉ . Effect of Framework Soldering on the Deformation of Implant Abutments After Framework Seating. Implant Dentistry (Print), v. 22, p. 193-198, 2013.

- AGOSTINI, C. E. ; CAPELLO SOUSA, E. A. . Complex modal analysis of a vertical rotor through finite element method. International Research Journal of Engineering Science, Technology and Innovation, v. 1, p. 111-121, 2012.

- HOLLWEG, H. ; JACQUES, L. B. ; MOURA, MARCIO DA SILVA ; BIANCO, V. C. ; SOUZA, EDSON ANTONIO CAPELLO ; RUBO, JOSÉ HENRIQUE. Deformation of Implant Abutments After Framework Connection Using Strain Gauges. The Journal of Oral Implantology, v. 38, p. 125-132, 2012.

- COSTA, M. D. ; LAURENT, M. A. ; BIANCO, V. C. ; MORETTI, Rafael Tobias ; CAPELLO SOUSA, E. A. ; RUBO, JOSÉ HENRIQUE. Análise comparativa da deformação gerada na região peri-implantar e no intermediário em função do aperto do parafuso protético em diferentes tipos de cilindros usinados e fundido. Implant News, v. 8, p. 87-92, 2011.

- TABATA,LUCAS FERNANDO ; GONÇALVES ASSUNÇÃO, WIRLEY ; BARÃO, VALENTIM ADELINO RICARDO ; ALVES GOMES, ERICA ; APARECIDA DELBEN, JULIANA ; CAPELLO DE SOUSA, EDSON ANTÔNIO ; PASSOS ROCHA, EDUARDO. Comparison of Single-Standing or Connected Implants on Stress Distribution in Bone of Mandibular Overdentures. Journal of Craniofacial Surgery, v. 21, p. 696-702, 2010.

Contact

CS3B – Centre for Simulation in Bioenginerring, Biomechanics and

Biomaterials

Engineering College of Bauru – UNESP, Campus of Bauru

Av. Eng. Luiz Edmundo C. Coube 14-01

Vargem Limpa - Bauru - São Paulo State, Brazil

CEP 17033-360.

Email: cs3b.unesp@gmail.com